What Is Laser Damage?

Laser damage is defined as "any permanent laser-radiation-induced change in characteristics of either the substrate or the coating".

Micrograph of Damage

Laser damage is caused by defects (weak bonds) within the structure. These are most commonly at the coating/substrate interface, or on the surface. Less commonly withing the bulk of the coating or substrate. The term ‘defect’ is a difficult concept when dealing with amorphous materials. However, we can say that the energy levels of these weakest bonds lie within the band gap. For further information on optics for high power laser damage, please see our whitepaper here.

Back to topWhat Is A Threshold Test?

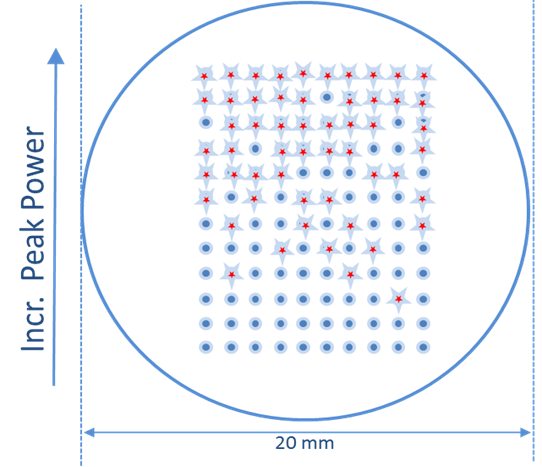

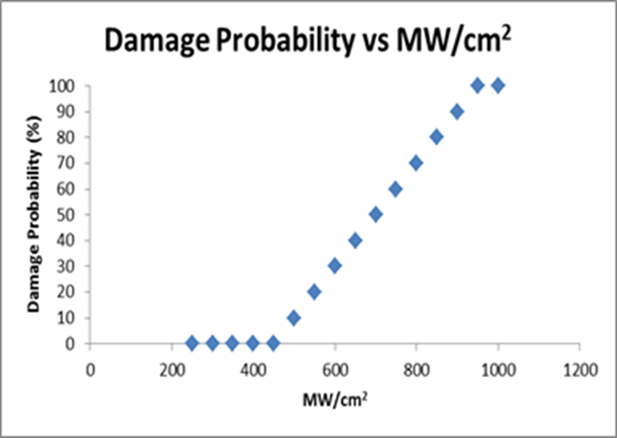

A ‘Laser Induced Damage Threshold’ (LIDT) test is the best definitive test for an optic, it determines the maximum laser power or energy the sample can take without damaging. Above the damage threshold, damage occurs. Because all coatings are glassy (amorphous) the test must be a statistical measurement, testing several sites at the same power level to determine its robustness at that level. A witness piece is irradiated at over 100 sites. There are usually 10 sites per row and each site is exposed to several laser pulses. The power level is altered appropriately for each row. We therefore need a minimum sample clear aperture of around 15 x 15 mm. Usually a 20 mm diameter witness piece is large enough. The damage incidents are recorded. As the pulse duration is fixed it is actually the beam energy which is varied, increasing row by row until a damage pattern is obtained. An ideal case is shown.

Information given here is to help buyers and coaters to get the most from their results. Often just a numerical result is what's required, however if you are developing a new product, graphical analysis can help establish your route to success. This is the most accurate means of establishing the Laser Induced Damage Threshold. The threshold value occurs at the x-axis intercept. In real life, it's not quite so uniform as in the above example. Any surface defects, as well as the quality of the coating process, can cause variations in the pattern. If a clear graphical is not possible then a least-fluence determination is given as the threshold.

The resulting LIDT certificate gives the damage threshold, the test conditions and the damage graph. We can discuss with you what the damage pattern means in terms of your coating quality; we give you more than just a number!

Our LIDT order forms for both pulsed and CW tests are available for download. Our white paper "High Power Pulsed & CW Laser Damage" gives more information. Our whitepaper "High Power Laser Damage & Annealing" gives a more scientific account of damage testing and overtesting. Our whitepaper "High Power Laser Damage - Threshold Elevation" details our study into common factors affecting damage testing.

Back to topWhat Is A Pass/Fail Test?

This is a simple test which certifies that a sample can withstand a customer-specified laser fluence. A number of sites across the sample are irradiated, and any laser induced damage constitutes a 'fail' result. This is a simpler test than a full threshold determination, and is often used for QA testing of standard coating runs.

Back to topWhat Are The Units For Laser Damage Testing?

The most commonly required tests are pulsed laser damage tests; the units are J/cm² (at a specified pulse duration) and MW/cm².

People differ in their preference J/cm² or MW/cm² BRL quotes all results in both units. However, the only accurate stand-alone unit is:

MW/cm²

This gives the peak power density (energy per unit time per unit area) which is the quantity being assessed in a laser damage threshold test. That is the highest peak power level that the coating can survive per unit area without permanent structural damage.

Specifications in J/cm² have to be quoted with the pulse duration to enable the power (MW/cm²) to be calculated. For example, if a coating has an LIDT of "500 MW/cm²" and this was obtained using 20 ns pulses then it would have an LIDT of "10 J/cm² at 20 ns". If the test was carried out at 10 ns and gave an LIDT threshold of 500 MW/cm², it would have an LIDT of "5 J/cm². Thus giving the J/cm² value without quoting the pulse duration is meaningless.

Continuous wave (CW) laser damage has a different dominant damage mechanism from the more common, pulsed laser damage which is described above. CW average power resistance is measured. It is dependent on spot size, which is not generally the case for pulsed laser damage. The units reflect this difference;

CW units are W/cm.

These units are not per area but per spot diameter (normally called spot size). Hence, your spot size on the optic will matter. The units are easily scale-able and a ready reckoner is given with your test results.

Back to topWhat Specifications & Samples Should I Send?

For pulsed tests most coaters will supply a sample in the format of a circular planar disc 20-25 mm diameter and approximately 2-3 mm thick. These are witness pieces and have the same substrate, substrate surface (prior to coating), and are included in the same coating run as the optic. Optics can also be tested but are more difficult and thus more expensive to test.

The necessary parameters are:

- AR or HR

- Test Angle

- Wavelength

- Pulse Duration

- Repetition Rate

- Cleaning Requirements e.g Solvent/Air

For CW tests we prefer two witness pieces as CW testing can render samples unusable and thus, one sample is used to find the region of the threshold and the other can be used to zero in on an accurate value.

The necessary parameters for CW tests are:

- AR or HR

- Wavelength

- Cleaning Requirements e.g Solvent/Air

Everything that we need to know is in our downloadable order forms for pulsed and CW laser damage.

Back to top